1. Introduction to MDF

Definition and Composition of MDF

Medium Density Fiberboard, commonly known as Medium Density Fiberboard(MDF), is a versatile engineered wood product made from wood fibers, wax, and resin. The fibers are compressed under high temperature and pressure, resulting in a dense and smooth panel. MDF is favored for its uniform texture, which makes it an ideal material for a variety of applications in construction and carpentry.

History and Evolution of MDF

The origins of MDF date back to the 1960s, when it was developed as an alternative to plywood. Initially, MDF was primarily used for interior applications, but over the years, its use has expanded to include a wide range of construction and carpentry projects. Its consistent quality and adaptability have contributed to its growing popularity.

Overview of MDF Manufacturing Process

MDF production begins with breaking down hardwood or softwood residuals into wood fibers. These fibers are then combined with wax and a resin binder, typically urea-formaldehyde, and formed into panels by applying high temperature and pressure. The result is a stable and durable board that can be cut, shaped, and finished with ease.

2. MDF vs. Other Wood Products

Comparison with Plywood

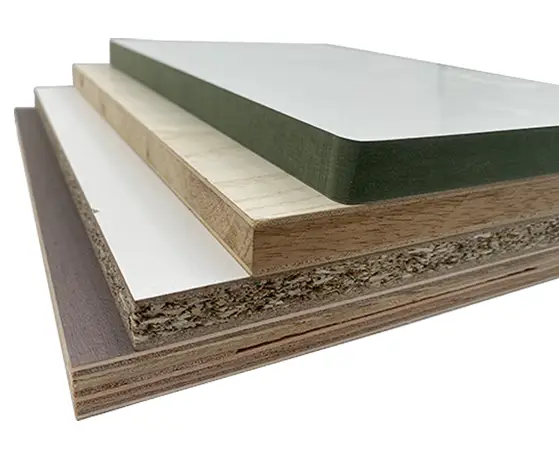

While MDF and plywood are both popular in construction and carpentry, they differ significantly in terms of composition and performance. Plywood is made by layering thin sheets of wood veneer, creating a cross-grain structure that provides strength and durability. MDF, on the other hand, is composed of wood fibers, giving it a smoother finish but less structural strength compared to plywood.

Comparison with Particleboard

Particleboard, like MDF, is an engineered wood product, but it is made from wood chips rather than fibers. This makes particleboard less dense and less smooth than MDF. MDF is generally stronger and offers a better surface for painting and finishing, making it a superior choice for visible applications like cabinetry and furniture.

Pros and Cons of MDF Compared to Natural Wood

MDF offers several advantages over natural wood, including cost-effectiveness, ease of machining, and a uniform surface ideal for painting. However, MDF is heavier than most natural woods and is more susceptible to moisture damage. Natural wood, while more expensive, offers greater strength and durability, especially in structural applications.