Particle Board

- Size: 1220mmx2440mm, (Customized Size)

- Thickness: 8mm, 9mm, 11mm, 12mm, 15mm, 18mm

- Core: Poplar, Pine, Eucalyptus

- Glue: MR E2 E1 E0 ENF PMDI WBP Melamine Phenolic

Reliable Quality, Sustainable Solutions: Your Trusted Chinese Chipboard Supplier.

Particle Board Manufacturer - Dongstar® - China Particle Board Wood Factory

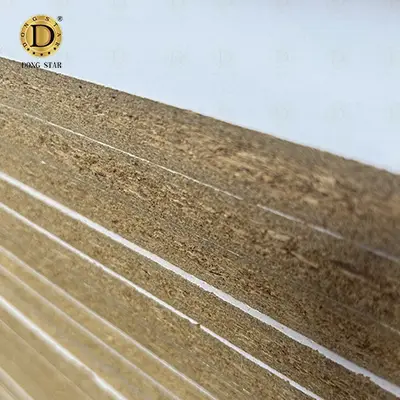

Particle board, also known as chipboard, is an engineered wood product made from wood particles, such as wood chips, sawmill shavings, and other wood residues. These chipboard are bonded together using synthetic resin or glue under high pressure and heat. Particle board is a cost-effective and versatile alternative to solid wood and plywood,

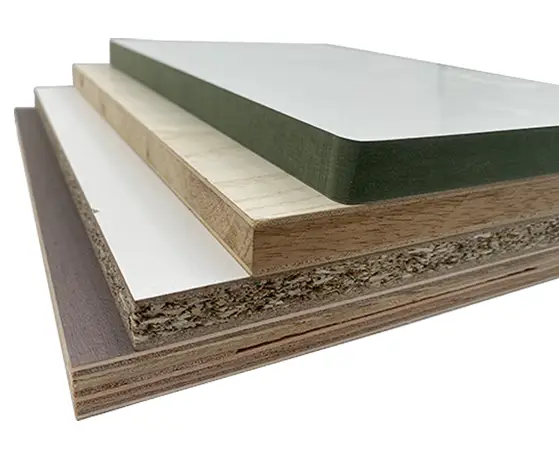

Particle Board Finish

As a well-known plywood manufacturer in China, Dongstar® prides itself on providing high-quality particleboard products that meet international standards. Particleboard is a versatile engineered wood product consisting of three basic components: veneer, glue and wood particles. Let’s delve into these components and understand their importance in particleboard construction.

Particle Board Core

Wood pellets, also known as flakes or chips, are the main raw material used in particleboard production. These particles are obtained by breaking down wood into small pieces. These are then mixed with glue and compressed under high pressure to form a strong panel. Wood pellets can be derived from various wood species including pine, poplar or eucalyptus, depending on availability and specific requirements. The size and composition of wood particles influence the density, strength and dimensional stability of particleboard.

Particle Board Glue

The glue used in particleboard is the key element that holds the wood particles together, ensuring the structural integrity and strength of the particleboard. Different types of adhesives are used and their quality plays a vital role in determining the performance of the particleboard. Commonly used glues are:

The choice of glue depends on the intended application, environmental conditions and desired performance characteristics.

Application

MDF can be used in various industries, including:

- Furniture Manufacturing: Particleboard is widely used in furniture manufacturing. It’s a great alternative to solid wood for its stability and cost-effectiveness.

- Interior Design and Decorative Panels: Particleboard panels can be used in a variety of interior design applications, including wall panels, ceilings, partitions and decorative screens.

- Doors and door cores: Particleboard is a reliable material for door construction. It can be used as a door core, providing stability and strength to the structure.

- Flooring systems: Particleboard can be used as a substrate for laminate or engineered wood flooring.