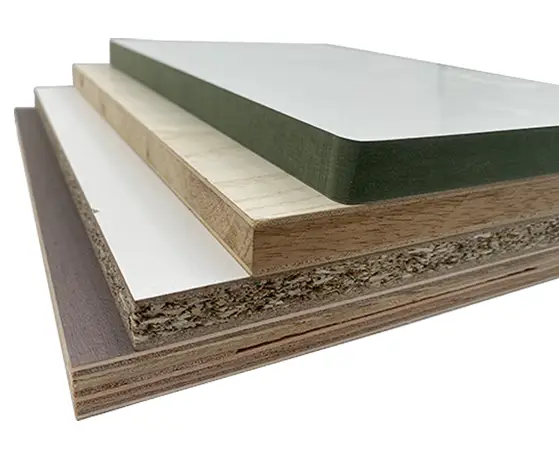

As a plywood manufacturer in China, Dongstar® is proud to be able to provide a wide range of core materials to meet various applications and customer requirements. Each core material brings unique characteristics and benefits to plywood construction, ensuring superior performance and durability. Let’s explore the different core materials we offer:

Birch Core

Birch is a dense and durable hardwood with excellent strength and stability. It is highly resistant to warping and has enhanced screw hold properties, meaning it is ideal for applications in the construction, furniture and joinery sectors.

Block Board

Blockboard is a type of plywood whose core is made of solid wood blocks. This core material has excellent dimensional stability and load-carrying capacity. Blockboard is commonly used in furniture, partitions and interior applications where strength and durability are required.

Combi Core

Combi Core plywood uses a combination of different tree species such as Eucalyptus and Birch for a balanced mix of strength, stability and cost-effectiveness. Combi Core is widely used in construction, flooring and general purpose applications.

Eucalyptus & Birch Core

The combination of Eucalyptus and Birch Core provides a plywood with the strength and durability of Eucalyptus and the refined finish and beauty of Birch. It is a popular choice for furniture, decorative applications and architectural projects.

Eucalyptus

Eucalyptus is known for its excellent strength-to-weight ratio and moisture resistance. Eucalyptus core plywood offers exceptional stability and is commonly used in construction, concrete formwork and exterior applications where durability is required.

Finger Joint

Finger-jointed core plywood is constructed by joining shorter pieces of wood using interlocking finger joints. This core material provides stability and reduces the risk of warping or splitting. It is suitable for a variety of applications including furniture, bookshelves and interior projects.

FR MDF

FR MDF (flame retardant medium density fiberboard) is a core material with flame retardant properties. It is often used in applications where fire safety is a concern, such as interior wall panels, partitions and furniture in public spaces.

Hardwood core plywood uses hardwood species such as oak, maple, or ash for added strength and durability. It is ideal for applications requiring excellent load carrying capacity, such as flooring, heavy furniture and industrial projects.

The core material of HDF core plywood is made of high density fiberboard, which has excellent dimensional stability and strength. HDF Core is suitable for applications where impact resistance and a smooth surface finish are critical, such as doors, cabinets and furniture components.

HMR MDF

HMR MDF (High Moisture Resistant Medium Density Fiberboard) is a core material that enhances moisture resistance. It is suitable for applications exposed to higher humidity, such as kitchen cabinets, bathroom furniture and interior woodwork.

Joint

Core-joint plywood consists of solid wood joints between adjacent veneers, providing increased strength and stability. It is commonly used in furniture, doors and trim applications where durability and aesthetics are important.

MDF core plywood features a core made of MDF for excellent stability, smoothness and uniformity. It is widely used on cabinets, bookshelves and interior projects requiring a consistent, flawless finish.

OSB Core plywood has a core made of oriented strand board, known for its strength and dimensional stability. It is commonly used in building, flooring and structural applications where reliable performance is required

Particleboard core plywood has a core made of small wood particles bonded together with resin. It is cost-effective and suitable for non-structural applications such as interior wall paneling, furniture backing and packaging.

Popular

Poplar core plywood is made of poplar, known for its light weight and uniform properties. It is widely used in furniture, cabinets and interior applications where stable and lightweight panels are required.

PVC

PVC core plywood uses a core material made of polyvinyl chloride, which has moisture resistance and dimensional stability. It is typically used in wet areas, such as bathrooms and kitchens, and in applications where resistance to chemicals or moisture is required.

RH Particle Board

The core material of RH particle board core plywood is made of moisture-proof particle board. It has enhanced durability and moisture resistance, making it suitable for applications in high humidity environments.

Rubber

Rubber Core plywood utilizes rubberwood, a sustainable and renewable resource, for the core material. It offers stability, durability, and ease of machining. Rubber Core plywood finds applications in furniture, cabinetry, and interior projects

Thicker core

Thicker core plywood is designed with a thicker core layer for extra strength and stability. It is suitable for applications requiring enhanced load carrying capacity and durability.

At Dongstar®’s plywood manufacturing plants, we offer a variety of core materials to meet our customers’ specific needs. Our commitment to quality ensures that our plywood with different core materials exhibits excellent performance, durability and versatility in a variety of applications.