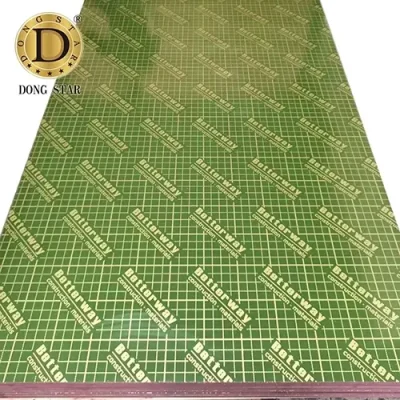

Green Film Faced Plywood Factory - Dongstar® - China Formwork Plywood Manufacturer

Introducing our premium Green Film Faced Plywood, specially crafted to meet the rigorous demands of the Middle Eastern market. This plywood panel stands out in the fields of construction, decoration, and furniture manufacturing across the Middle East, thanks to its exceptional durability, stability, and eco-friendliness.

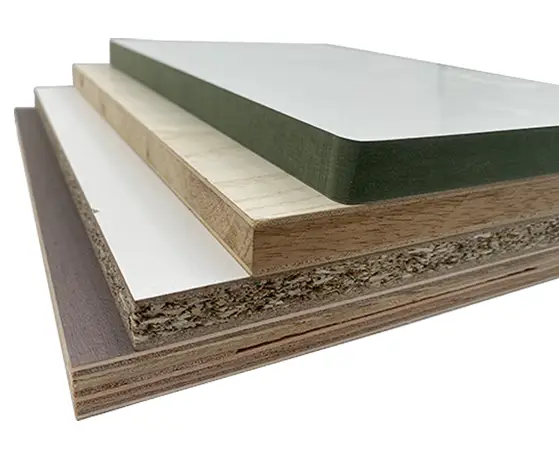

Core material

Plywood core materials play a crucial role in determining the strength, durability, and overall quality of the plywood.

The choice of plywood core material depends on the specific requirements of the application, considering factors like strength, stability, moisture resistance, and cost.

Eco-Friendly Material: Made from high-quality raw wood that undergoes stringent selection and processing, ensuring each layer meets environmental standards. The surface is covered with a green film, which not only enhances aesthetics but also helps reduce the emission of harmful substances like formaldehyde, providing a healthy living environment.

High Strength and Stability: Utilizing advanced production techniques and precise lamination technology, Green Film Faced Plywood exhibits outstanding bending strength and load-bearing capacity. It maintains stable performance, resistant to deformation or cracking, even in extreme climatic conditions such as the high temperatures and arid environments of the Middle East.

Wear and Scratch Resistance: The green film surface undergoes special treatment, offering superior wear and scratch resistance. Suitable for various applications where durability and aesthetics are paramount, it ensures long-lasting performance with minimal maintenance.

Glue Types

When it comes to plywood glue, two common types used for their superior bonding properties are WBP Melamine and WBP Phenolic.

WBP Melamine Glue:

WBP Melamine (Water Boiled Proof Melamine) is a synthetic resin adhesive.

It is known for its excellent water resistance and durability, making it suitable for exterior and marine applications.

WBP Melamine glue creates a strong bond that can withstand exposure to moisture, humidity, and changes in temperature.

It is commonly used in construction, concrete formwork, flooring, and other applications where plywood needs to withstand harsh environmental conditions.

WBP Phenolic Glue:

WBP Phenolic (Water Boiled Proof Phenolic) is a synthetic resin adhesive derived from phenol formaldehyde.

It is highly resistant to moisture, heat, and chemicals, making it ideal for both interior and exterior applications.

WBP Phenolic glue provides excellent bonding strength and stability, ensuring the plywood can withstand heavy loads and extreme conditions.

It is widely used in construction, furniture manufacturing, packaging, and other demanding applications that require durable and reliable plywood.

Both WBP Melamine and WBP Phenolic glues are engineered to meet stringent quality standards and provide long-lasting bonding performance. The choice between the two depends on the specific requirements of the project, including the intended application, environmental exposure, and desired durability.

Film Types

Supplied to Azizi: Proudly serving clients like Azizi, our Green Film Faced Plywood has been recognized for its quality and reliability in major projects across the Middle East. This partnership underscores our commitment to delivering top-notch products that meet the highest standards in the region.

Market Focus – Middle East:

Specifically tailored for the Middle Eastern market, our Green Film Faced Plywood is designed to withstand the unique challenges of the region’s climate and construction practices. Its combination of durability, eco-friendliness, and aesthetic appeal makes it an ideal choice for a variety of projects, from high-rise buildings to luxurious homes.

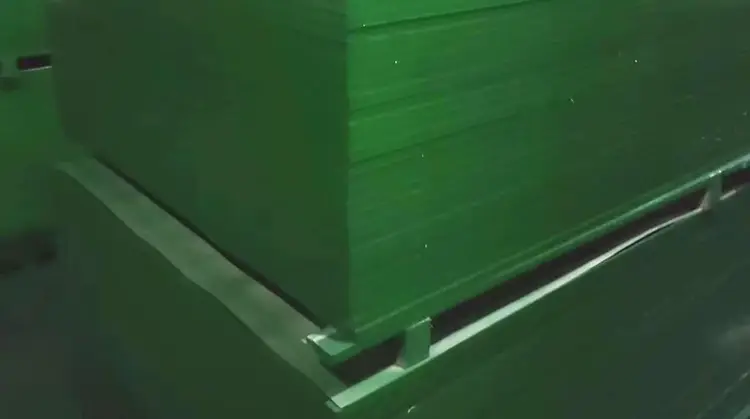

Edge Seal - Waterproof

Waterproof edge sealing is an essential step in plywood protection and longevity. It helps prevent moisture penetration and protects the edges from damage.

Remember, proper edge sealing is crucial to maximize the performance and longevity of form plywood, particularly in applications where exposure to moisture is expected. By taking the necessary precautions and using high-quality sealants, you can ensure the long-term durability and water resistance of your plywood products.

CONTACT US

We will answer your email shortly!

Don’t want to be tied down? Click to send email directly dongstarplywood@gmail.com

Form Plywood Applications