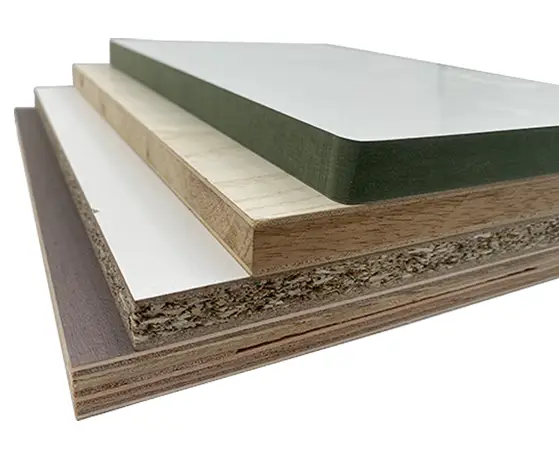

Fancy Plywood

- Name: Fancy Plywood

- Size :1220x2440mm,1250x2500mm,1250x3000mm,or as Customized

- Thickness: 2.7~30mm

- Face/Back: Parota

- Core Material: Birch,Eucalyptus,Poplar,Combi core,Pine,MLH or as request

- Grade: BB/BB,BB/CC,C/D

- Glue: MR,E0,E1,E2

- Glue emission level: E0, E1, E2

- Surface Treatment: Polished/Non-Polished

- Density: 500-750kg/m3

- Moisture Content: 8%~14%

- Usage: Furniture,Cabinet,Construction,Packing,etc

- Certification: FSC,CE,EUTR,CARB,EPA

Decorative plywood, also known as fancy plywood or veneer plywood, is a type of engineered wood product that features a decorative face veneer on both sides. It is created by bonding thin slices of natural wood veneer to a plywood core using adhesive under high pressure and heat. The decorative veneer gives the plywood an attractive appearance, making it ideal for aesthetic applications in interior design, furniture manufacturing, and decorative finishes.

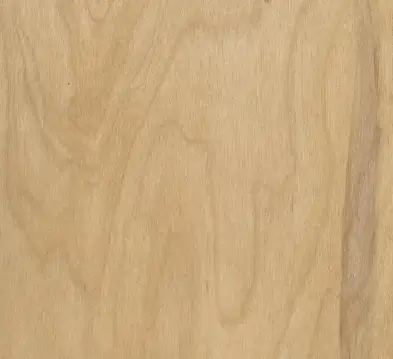

Core

Commercial Grade

- Core: Poplar/MDF/HDF/Blockboard

- Face: Bintangor, Pine, EV, Okoume

- Glue: Urea-Formaldehyde (E1, E2)

Features: The price of fancy plywood made of MDF and HDF is very low, but its strength will face great challenges. Therefore, it is a correct choice to use MDF on some non-load-bearing structures.

Furniture Grade

- Core: Poplar/Eucalyptus/Blockboard

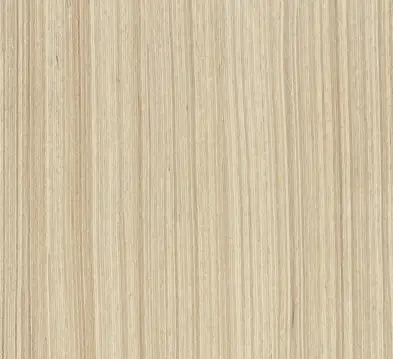

- Face: Bleached Poplar, , EV, Burma Teak, Red Oak, Ash, Okoume, Pine, Birch, Oak, Walnut

- Glue: Urea-Formaldehyde (E0, E1)

Features: Made of affordable Chinese poplar wood, the thinnest thickness is 2.5mm and the largest thickness is 25mm. Can be customized according to customer needs, such as MDF core.

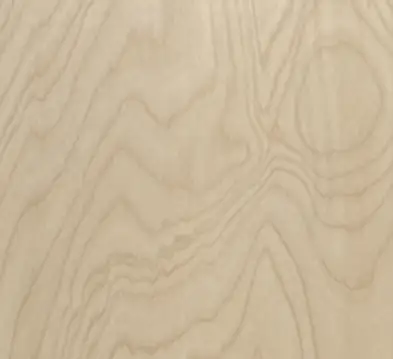

WBP Grade

- Core: Poplar/Eucalyptus

- Face: Okoume, Bintangor, Pine, Birch

- Glue: Melamine UF, Phenolic UF

Features: It’s expensive, but it’s strong, and it’s very reliable when used on load-bearing structures.

Veneer

Glue Types

The main differences among melamine glue, urea-formaldehyde glue, and phenolic glue lie in their water resistance, durability, and application suitability. Melamine glue excels in water resistance, making it suitable for marine and exterior applications. Urea-formaldehyde glue is cost-effective and commonly used in general-purpose woodworking. Phenolic glue offers exceptional strength and durability, making it ideal for demanding applications that require superior water resistance and long-term performance.

Urea-Formaldehyde(UF)

Urea-formaldehyde glue is a thermosetting adhesive made by combining urea and formaldehyde. It offers good bonding strength and is widely used in the woodworking industry. Urea-formaldehyde glue is cost-effective, easy to use, and provides a strong bond. It is suitable for general-purpose woodworking applications and is commonly used in furniture manufacturing and interior construction.

Compared to melamine glue, urea-formaldehyde glue has lower water resistance and may not be suitable for applications exposed to high moisture levels. However, it is still widely used in interior applications where water exposure is minimal, and cost-effectiveness is important.

Melamine

Melamine glue is a synthetic resin adhesive that is known for its excellent water resistance and durability. It is made by combining melamine resin with formaldehyde. Melamine glue creates a hard and smooth surface when cured, providing a high-quality finish. It is resistant to heat, chemicals, and moisture, making it suitable for applications that require enhanced durability and resistance to wear and tear.

Melamine glue differs from other adhesives in terms of its moisture resistance and smooth finish. It is commonly used in applications where water resistance is crucial, such as in marine construction, exterior applications, and furniture manufacturing.

Phenolic

Phenolic glue, also known as phenol-formaldehyde glue, is a high-performance adhesive with excellent strength, durability, and resistance to moisture, heat, and chemicals. It is made by combining phenol and formaldehyde under high temperature and pressure. Phenolic glue provides exceptional bonding strength and is commonly used in demanding applications that require superior water resistance and durability.

Phenolic glue surpasses both melamine glue and urea-formaldehyde glue in terms of its water resistance and durability. It is commonly used in applications such as marine construction, exterior building materials, and structural applications that require exceptional strength and long-term durability.

Veneer Faced Plywood Application

CONTACT US

We will answer your email shortly!

Don’t want to be tied down? Click to send email directly dongstarplywood@gmail.com