Table of Contents

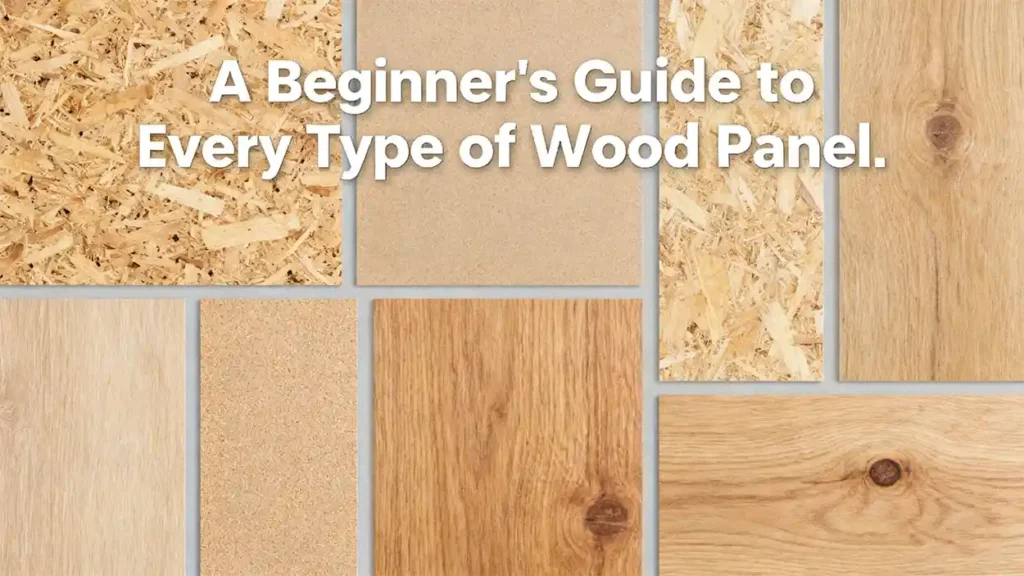

Walking into a lumber yard can be overwhelming with all the wood panel options: plywood, MDF, OSB, and more. It’s easy to choose the wrong one. This beginner’s guide cuts through the confusion. We’ll break down each type of wood panel, its core characteristics, and its ideal project, helping you buy the right material with confidence.

Plywood: The All-Round Workhorse

More Than Just Layers of Wood

Plywood is the versatile champion of the workshop and job site. It’s made by gluing together thin layers of wood veneer, called plies, with the grain of each layer perpendicular to the next. This cross-graining technique is what gives plywood its incredible strength and resistance to cracking, shrinking, and warping. You’ll find it in everything from furniture and cabinetry to structural sheathing and subfloors. However, not all plywood is the same. Its quality and suitability are determined by its grade, core type, and the specific adhesive used.

Breaking Down Common Plywood Types

Navigating plywood labels is key to a successful project. Here’s a quick rundown:

- Softwood Plywood: Typically made from Douglas fir or pine, this is your go-to for structural applications. You’ll find it used as wall sheathing, roof decking, and subflooring.

- Hardwood Plywood: Made from woods like oak, maple, or birch, this type is valued for its strong, durable surface and attractive grain. It’s the top choice for fine furniture, cabinets, and built-ins where the finished appearance matters.

- MR Grade (Moisture-Resistant): Often called “Interior” plywood, it uses water-resistant glue. It’s fine for kitchens and bathrooms where occasional humidity is expected, but it shouldn’t be constantly wet.

- Marine Grade Plywood: This is the gold standard for wet environments. Made with waterproof glue and high-quality, solid veneers without core gaps, it’s designed to withstand prolonged exposure to moisture. It’s essential for boat building and exterior projects.

The Other Major Players: MDF, Particle Board, and OSB

MDF: The Smooth Operator

Medium Density Fiberboard (MDF) is made from broken-down wood fibers mixed with resin and pressed into dense, flat panels. Its greatest advantage is its perfectly smooth, uniform surface that has no grain. This makes it ideal for painting, and it’s easy to cut and shape for detailed moldings and trims. The downsides? It’s very heavy, and unless you get a moisture-resistant version, it soaks up water like a sponge and can swell dramatically.

Particle Board: The Budget Choice

Particle board is the most economical option. It’s manufactured from wood chips, sawdust, and resin pressed together. You’ll often find it as the core material in ready-to-assemble furniture covered with a laminate or veneer. While cheap and lightweight, it has significant drawbacks: it’s weak, doesn’t hold screws well, and is highly susceptible to moisture damage, making it unsuitable for any load-bearing or damp areas.

OSB: The Structural Powerhouse

Oriented Strand Board (OSB) is easily identified by its distinctive look of compressed wood strands. These strands are arranged in cross-oriented layers and bonded with waterproof adhesives, creating a panel with tremendous shear strength. OSB has largely replaced plywood for many structural applications like wall sheathing, roofing, and subflooring. While its rough surface isn’t suited for fine furniture, it’s a cost-effective and strong engineered wood.

Choosing the Right Panel for Your Project

Making the right choice comes down to your project’s specific needs. Ask yourself these questions:

- Where will it live? For interiors, hardwood plywood or MDF are great. For exteriors or wet areas, you need Marine Grade plywood or treated materials.

- What’s the finish? If you’re painting, MDF provides the smoothest finish. If you want a natural wood look, hardwood plywood is your best bet.

- How much strength is needed? For structural walls or floors, choose OSB or softwood plywood. For bookshelves and furniture, hardwood plywood or MDF will suffice.

- What’s your budget? Particle board is the cheapest, followed by OSB and softwood plywood, with hardwood and Marine Grade plywood at the higher end.

For a new subfloor, OSB is a standard, cost-effective pick. For built-in living room shelves you plan to paint, MDF is perfect. For a beautiful kitchen table, hardwood plywood with a nice veneer is the way to go.