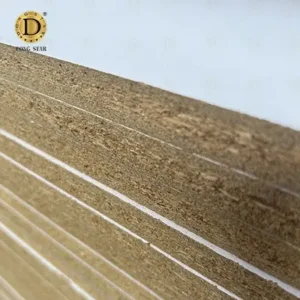

Particle Board from China is a popular engineered wood product made from wood chips, sawdust, and other wood fibers that are bonded together with a resin and compressed to form a solid sheet. It is widely used in furniture manufacturing, interior construction, and other applications. Here’s an in-depth look at particle board produced in China:

Manufacturing Process of Particle Board

The production process of particle board involves several key steps:

Raw Material Collection: The wood particles, which can include sawdust, wood chips, and even recycled wood, are gathered from various sources.

Wood Fiber Preparation: The raw materials are processed and ground into fine particles or chips.

Mixing with Resin: The wood fibers are mixed with a resin (often formaldehyde-based) to bind them together. Additional chemicals may be added to enhance properties like moisture resistance and strength.

Pressing: The mixture is placed into large presses where it is subjected to high pressure and temperature, forming a solid sheet.

Cutting and Finishing: The boards are then cut to size and finished with sanding or lamination for smoothness and aesthetics.

Types of Particle Board

Particle board can come in various grades and qualities based on its intended use:

Standard Particle Board: Typically used for furniture, cabinetry, and internal structures.

High-Density Particle Board: Offers greater strength and durability, often used for flooring and heavy-duty applications.

Moisture-Resistant Particle Board: Has added chemicals to improve resistance to water, commonly used in kitchen or bathroom furniture.

Flame-Retardant Particle Board: Treated with fire-resistant chemicals to meet fire safety standards.

Advantages of Chinese Particle Board

Cost-Effective: Particle board is generally cheaper than other wood-based products like plywood, making it an economical choice for mass production, especially in furniture manufacturing.

Eco-Friendly: Using recycled wood fibers and by-products in the production of particle board helps reduce waste and makes it a more sustainable option compared to solid wood products.

Versatility: Particle board can be laminated, veneered, or painted to match various interior designs, making it suitable for a wide range of applications, including furniture, flooring, and wall panels.

Smooth Surface: Due to its uniform density and smooth finish, particle board provides a good base for applying veneers, laminate, or paints.