Plywood Design

As a reputable plywood manufacturer from China, Dongstar® takes pride in delivering top-quality plywood products that meet international standards. Plywood is a versatile building material known for its strength, durability, and wide range of applications. Let’s delve into the three fundamental components that make up plywood: the core material, glue, and veneer film.

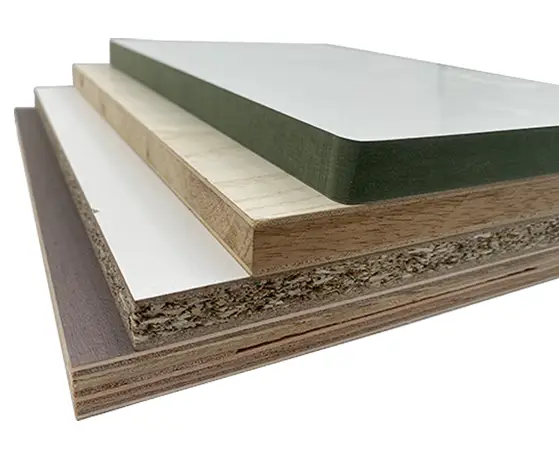

Core Material:

The core material forms the backbone of plywood, providing structural integrity and stability. Different types of core materials are used based on specific application requirements. Common core materials include:

- Poplar Core: Poplar is a lightweight, sustainable, and cost-effective core material. It offers excellent stability, uniformity, and ease of machining. Poplar core plywood is suitable for various interior applications.

- Birch Core: Birch is a dense and durable hardwood known for its exceptional strength and stability. Birch core plywood exhibits superior screw-holding properties and resistance to warping, making it ideal for demanding applications in construction and furniture.

- Eucalyptus Core: Eucalyptus is valued for its strength, moisture resistance, and dimensional stability. Eucalyptus core plywood is widely used in exterior applications and concrete formwork due to its durability and resistance to moisture.

- Finger Joint Core: Finger joint core plywood is constructed by joining shorter pieces of wood using interlocking finger joints. This core material enhances stability and reduces the risk of warping or splitting, making it suitable for various interior applications.

Glue:

The glue used in plywood is crucial for bonding the layers of veneer together, providing strength and durability. Different types of glues are employed based on the intended application and performance requirements. Some common types of glues include:

- Phenolic Glue: Phenolic glue is widely recognized for its exceptional durability and moisture resistance. It is commonly used in exterior-grade plywood or applications exposed to high humidity and weathering conditions.

- WBP (Weather and Boil Proof) Glue: WBP glue is specifically formulated for enhanced water resistance. It is suitable for applications that require protection against moisture or water exposure, making it popular in marine and construction industries.

- MR (Moisture Resistant) Glue: MR glue provides moderate moisture resistance and is suitable for interior applications where limited exposure to moisture is expected.

These are just a few examples of glues used in plywood manufacturing. The choice of glue depends on factors such as application, environmental conditions, and desired performance characteristics.

Veneer Film:

The veneer film, also known as the face or surface layer, is a thin decorative covering applied to the plywood panels. It enhances the visual appeal of the plywood and protects it from external elements. Common types of veneer films include:

- Natural Wood Veneer: Natural wood veneer offers the authentic beauty and texture of different wood species, providing a luxurious and elegant finish. It allows for a wide range of aesthetic options and is popular in high-end furniture and architectural applications.

- Artificial Veneer: Artificial veneer is a synthetic material that replicates the appearance of natural wood. It offers consistency in color and grain patterns, making it a cost-effective alternative for achieving specific design aesthetics.

- Film-faced Veneer: Film-faced veneer is a specialized film that provides added protection and durability to plywood panels. It is commonly used in applications that require resistance to abrasion, moisture, and chemical exposure.

The veneer film not only enhances the visual appeal but also adds an extra layer of protection, ensuring the longevity and performance of plywood in demanding applications.

At Dongstar®, we recognize the significance of each component in producing high-quality plywood. Our commitment to using premium core materials, reliable glues, and aesthetically pleasing veneer films ensures that our plywood products meet the highest industry standards. With our comprehensive understanding of these essential components, we strive to deliver plywood solutions that exceed customer expectations in various construction, furniture, and interior design projects.

CONTACT US

We will answer your email shortly!

Don’t want to be tied down? Click to send email directly dongstarplywood@gmail.com