3 Layer Plywood Factory - Dongstar® - China Formwork Plywood Manufacturer

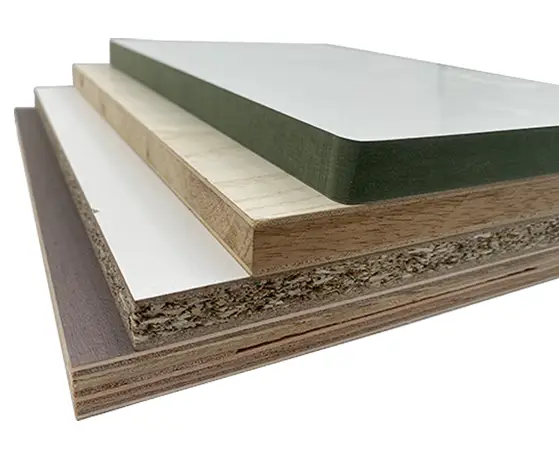

Our 3 Layer Plywood is a high-performance, cost-effective plywood panel designed especially for large-scale construction and commercial projects. With a simple yet robust three-ply construction (core layer sandwiched between two face veneers), it offers stable dimensional performance, good strength, and ease of processing.

This product is engineered to meet the demands of builders, contractors, project developers, and furniture or joinery manufacturers who require bulk supply, consistent quality, and reliable delivery.

Core material

Plywood core materials play a crucial role in determining the strength, durability, and overall quality of the plywood.

The choice of plywood core material depends on the specific requirements of the application, considering factors like strength, stability, moisture resistance, and cost.

Why Choose Dongstar 3 Layer Plywood Sheets? – Market & Project Demand

- The global plywood market is experiencing steady growth, driven by increasing urbanisation, infrastructure, renovation and commercial construction activities.

- For large-scale projects (commercial buildings, hotels, factories, formwork, packaging) the need for bulk supply, consistent board quality, and efficient logistics is critical.

- The three-layer structure offers a favourable cost-performance ratio compared to multi-ply (5-,7-,9-ply) boards — ideal for applications where core strength, stability and surface finish are sufficient, yet cost must be controlled.

- As many B2B buyers, wholesalers and project-procurement teams look for plywood with proven sourcing, certification and competitive minimum order quantities, this product covers precisely that demand.

Core Product Advantages

Exceptional Structural Stability |

|

Superior Durability & High Reuse Rate |

|

Excellent Concrete Finish |

|

Strict Environmental & Safety Standards |

|

Why Choose Dongstar 3 Layers Plywood for Project Application?

- Large capacity & dedicated production line: able to serve container volumes with consistent lead times and bulk pricing.

- Project-oriented service: we understand procurement for large builds – documentation, QA reports, shipment tracking, packaging optimised for cost-effective freight.

- Customisation available: we accommodate custom sizes, branding (if required), special veneer faces, special orders for large-scale builds.

- Global shipping capability: we ship worldwide, support bulk orders, and provide FOB / CIF / DDP terms on request.

- Competitive pricing for bulk orders: by leveraging our production efficiency and logistics, we offer strong margins for B2B partners, wholesalers, and project buyers.

- Sustainability commitment: we source timber responsibly, hold relevant certifications, and support clients’ green building targets.

FAQ

- What is the minimum order quantity (MOQ)?

For wholesale/bulk orders we typically require one 20-ft container or equivalent volume; for large projects we can negotiate flexibility. - Can you supply customised sizes or grades?

Yes — based on volume, we accommodate non-standard sizes, special veneer types, custom thickness, branding or packaging requirements. - What is lead time?

Typical lead time is 2-10 weeks after order confirmation and deposit; for blanket contracts we can arrange scheduled shipments. - How is the plywood packed for shipment?

Palletised, wrapped, placed in containers by truck to port; we can coordinate freight forwarding or accept buyer’s forwarder. - Are environmental certifications available?

FSC / CE / E0/E1 formaldehyde emission certificates available on request. Useful for green-building or export projects. - What is the pricing structure?

Pricing depends on volume, size, thickness, grade, certification and freight terms. Bulk orders qualify for significant discounts compared to retail or small-order rates.

For builders, project developers, wholesalers and B2B buyers seeking a cost-effective, bulk-friendly, reliable plywood solution, our 3 Layer Plywood offers the sweet spot of structural performance, supply chain efficiency and project-scale logistics readiness. Whether you’re outfitting a high-rise building, deploying modular furniture across a chain of hotels, or sourcing crates for export shipping, our board is engineered for the demands of large-scale procurement.

Contact us today to discuss your required specification, volume, shipment schedule and negotiate your best price for the upcoming project.

CONTACT US

We will answer your email shortly!

Don’t want to be tied down? Click to send email directly dongstarplywood@gmail.com